Biology. Biomimetics. Biotechnology.

DESIGNED FOR MEN. FOR BETTER RESULTS.

Powered by B³OS+™ - The first and only clinical R&D framework built for men’s skin, rooted in nature and proven to perform.

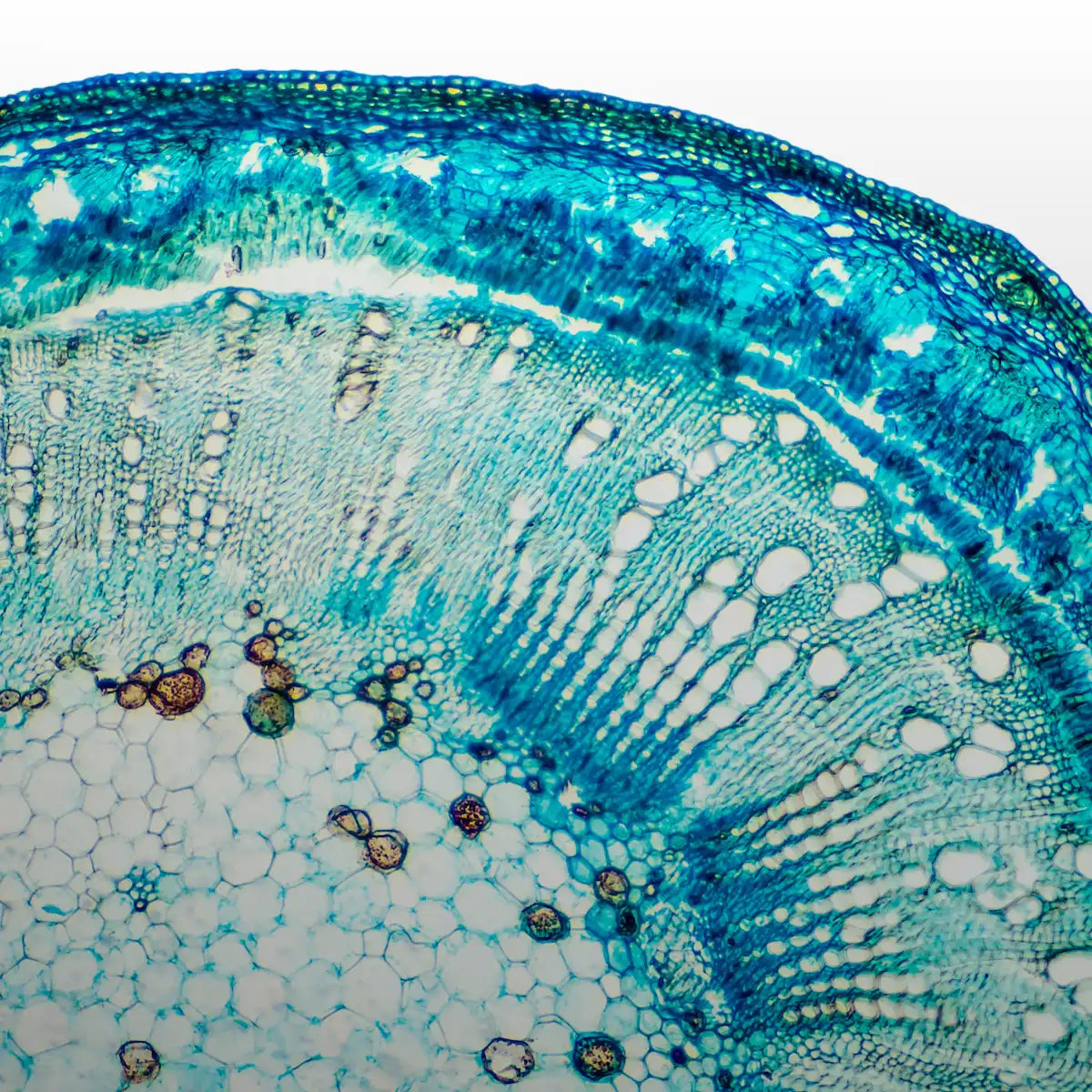

Biomimetics. Ingredients That Act Like Skin

Our formulas mimic the skin’s natural pathways, more effectively targeting unique-to-men concerns.

Not All Exosomes are created equal

Not All Exosomes are created equal

Patent-Pending Exosome Technology

Exosomes are messengers that carry active ingredients, delivering them deep within skin. These are the first biomimetic, plant-based exosomes engineered for men’s skin. 1000x smaller than pores, actives are guided to the right layer of skin for improved efficacy.

Our collection of proven ingredients

Adaptobiome™

ExoDense™ Complex

PhytoRecovery Complex

Soothing Botanical Complex

Biotech protects nature. Our sustainable standards.

Biotech protects nature. Our sustainable standards.

-

Preserves Biodiversity

Use of plant cells and fermentation reduces our reliance on overharvested botanicals, and enhances ingredient potency and consistency.

-

Zero Toxins, Full Transparency

No petrochemicals, parabens, phthalates, microplastics, colorants or synthetic fragrances. Only clinically-proven, safe formulations crafted with environmental integrity.

-

Glass-First, Plastic-Neutral

Prioritizing glass over plastic, and backed by a Plastic Neutral Certification, results in our low-impact packaging footprint.